Hi, I hope you might be wondering about preparing an estimate of a project before beginning. This guide serves as an informational resource to assist you in understanding the key elements of project estimation techniques, especially the project estimation technique.

For a project to be completed within the committed margin, it is an art to develop an on-ground estimate by collecting all the data in its actual format.

Understanding the project estimation technique is crucial for effective project management and achieving desired outcomes.

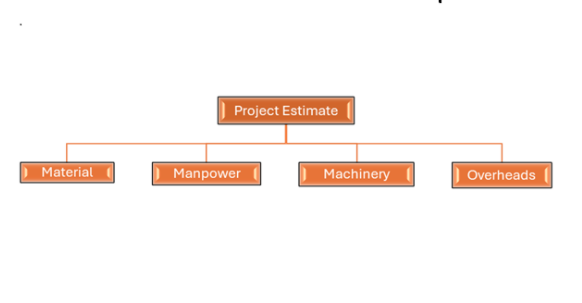

For a project estimate, the 3Ms play a key role, followed by overheads. Overheads include expenses like staff salary, facility costs, staff welfare, CSR (corporate social responsibility), electricity, and water charges (if applicable).

1. Material

By employing various project estimation techniques, project managers can enhance their estimating capabilities and ensure projects are completed on time and within budget.

By using this informational guide, project managers can enhance their estimating capabilities and ensure projects are completed on time and within budget.

In any project estimation technique, it’s vital to consider both direct and indirect costs related to project delivery.

The project estimation technique enables project managers to assess risks and allocate resources efficiently.

Understanding how to create an effective project estimation technique is essential for anyone involved in project management. This informational overview will highlight the main components that need to be considered.

2. Manpower

3. Machinery

4. Overheads

Let’s talk about each part one by one.

In this informational section, we will discuss how material estimation can impact overall project efficiency and success.

In this informational section, we will delve into the various factors that influence project estimation.

This informational guide will explore the importance of accurate project estimation techniques and how they can influence project success through effective project estimation technique application.

1. Material

For completing the project, if it falls under an item rate contract, EPC contract, or other types of contracts, materials are generally provided by the contractor. However, in some exceptional cases, material supply can be monitored and supplied by the client.

Let’s break down the material requirements based on priorities and financial implications.

I. High-Value Items

These materials need precise procurement as once ordered and delivered, they require close monitoring. Key examples include cement, aggregate, and structural steel (depending on the project).

While estimating these materials, the following factors must be considered:

a) Rolling margin of reinforcement—This is the difference between the theoretical quantity and the actual weight of material received at the site, generally considered as a percentage.

b) Wastage of bulk materials – As we know, there will always be some wastage, especially for bulk materials like cement, sand, aggregate, admixture, and steel.

c) Lead time for procurement – High-value materials often have longer procurement times, so planning should factor in lead times to avoid project delays.

Note: While estimating the material requirement, we should consider wastage. If not accounted for properly, it will directly impact material costs and project margins.

II. Special Material (Project-Specific Material)

This refers to materials required specifically for a project and cannot be procured easily. For example, if the site is in a remote location or hilly terrain, certain materials become crucial for project deliverables.

III. Standard Consumables

These are general materials required for most projects, such as nails, binding wire, bolts, adhesives, and safety gear. While these items may not be expensive individually, their collective cost can impact the project budget significantly.

How to Calculate Material Requirements?

Considering the project scope and deliverables, we will have estimated quantities from the client’s side. This means all activities involved in the project will be identified, allowing us to determine the required materials based on these activities.

To accurately estimate materials, the following approach can be followed:

Having an informational framework for estimating materials will allow for better planning and execution of the project estimation technique.

- Review the project drawings and specifications.

- Conduct a material take-off (MTO) for each construction phase.

- Factor in material wastage and losses.

- Compare estimates with historical data from similar projects.

- Consider logistics and storage conditions to prevent damage or loss.

By following this structured approach, we can ensure a precise and efficient project estimation process.

2. Manpower

In this informational overview, we will highlight the various overhead costs that need to be accounted for in project estimation.

Manpower plays a crucial role in project estimation, as it directly affects timelines, quality, and efficiency. Proper workforce planning helps in optimizing productivity and controlling costs.

Categories of Manpower:

The project estimation technique should be evaluated regularly to capture lessons learned for future projects.

- Skilled Labor – Includes masons, carpenters, welders, electricians, and other specialized workers who require training and expertise.

- Unskilled Labor – Includes general laborers responsible for assisting skilled workers in various tasks.

- Supervisory Staff – Includes site engineers, foremen, and quality control personnel who oversee project execution.

- Administrative Staff – Includes project managers, planners, accountants, and HR personnel managing project operations.

- Contractual vs. Permanent Workers – Some projects require contractual labor to reduce overhead costs, while others may need a permanent workforce for long-term operations.

How to Estimate Manpower Requirements?

- Identify all project activities and break them down into tasks.

- Calculate the number of work hours required for each task.

- Determine labor productivity rates based on historical data or industry standards.

- Factor in shifts, overtime, and any additional allowances for remote or challenging site conditions.

Factors Affecting Manpower Estimation

- Work complexity: More complex tasks require highly skilled workers.

- Weather conditions: Extreme weather can slow down productivity.

- Availability of skilled labor: Some projects may require hiring from different regions.

- Safety measures: Additional training or safety protocols may increase labor costs.

Proper manpower estimation ensures efficient resource utilization, reducing the risk of delays and cost overruns.

3. Machinery

Machinery and equipment are essential for executing a project efficiently. The selection of machinery depends on project size, complexity, and terrain.

Types of Machinery:

- Earthmoving Equipment – Excavators, bulldozers, loaders, and backhoes used for land clearing and excavation.

- Material Handling Equipment – Cranes, forklifts, and hoists used for lifting and transporting materials.

- Concrete Equipment – Mixers, batching plants, and pumps used for concrete production and placement.

- Road Construction Equipment – Pavers, rollers, and graders used for road and pavement works.

- Miscellaneous Equipment – Generators, welding machines, and scaffolding necessary for supporting construction activities.

How to Estimate Machinery Requirements?

- Identify the type of machinery required for each activity.

- Calculate usage duration based on work schedule.

- Consider maintenance, fuel costs, and rental/purchase expenses.

- Account for standby equipment to avoid delays due to breakdowns.

Best Practices in Machinery Estimation

- Optimize equipment utilization: Ensure machinery is not idle for long durations.

- Compare rental vs. purchase costs: Some equipment is better rented than owned.

- Include fuel and maintenance costs: Neglecting these can lead to budget overruns.

- Plan for contingencies: Backup equipment should be considered in case of breakdowns.

Optimizing machinery usage ensures smooth operations, minimizing project downtime and unnecessary expenses.

4. Overheads & Contingencies

Apart from direct costs related to materials, manpower, and machinery, several indirect costs must be considered.

Overhead Costs Include:

- Staff Salaries – Payment for engineers, managers, and office staff.

- Site Facilities – Offices, canteens, accommodation, and utilities.

- Equipment Maintenance – Repair and upkeep of tools and machinery.

- Safety Measures – PPE kits, first aid, and fire safety equipment.

- CSR (Corporate Social Responsibility)—Any obligations towards the community, such as infrastructure improvements or donations.

- Electricity & Water Charges – If applicable, these utilities must be included in the estimate.

Contingency Planning

Even with meticulous planning, unexpected challenges arise. A contingency fund (usually 5-10% of total costs) is recommended to address:

Implementing a robust project estimation technique can significantly enhance communication among project stakeholders.

- Market fluctuations in material costs.

- Delays due to weather or supply chain disruptions.

- Unexpected design changes or additional work.

Conclusion

A well-structured project estimate covering material, manpower, machinery, overheads, and contingencies helps in achieving project success within budget. Proper planning, monitoring, and adjustments based on real-time site conditions ensure that cost overruns are minimized and project margins are maintained. By following these principles, you can develop a reliable and practical project estimate, setting a strong foundation for successful project execution.

Accurate estimation not only improves financial planning but also enhances project efficiency, ensuring timely delivery and quality execution. By integrating data-driven decision-making, learning from past projects, and leveraging modern tools like project management software, estimation accuracy can be significantly improved, reducing risks and ensuring project success

This informational guide will also provide insights into contingency planning and its significance in project estimation.

As a final note, this informational approach to project estimation will highlight the project estimation technique as a vital component for ongoing improvements in project management practices.

Using this informational methodology can greatly enhance the overall quality of project delivery and client satisfaction.

This informational guide will also provide insights into the project estimation technique and its significance in project management.

Using this informational methodology, particularly the project estimation technique, can greatly enhance the overall quality of project delivery and client satisfaction.